Mechanical eccentric presse - 6T

Characteristics of the range

•Frame

The frame is made of high quality mechanized-

welded steel with swan-neck structure. Regular

weld seams and proper welding supports ensure an

exceptional rigidity and a resistance against cutting

impacts even during an intensive use.

The very thick sides of the frame reduce the swan-

neck opening.

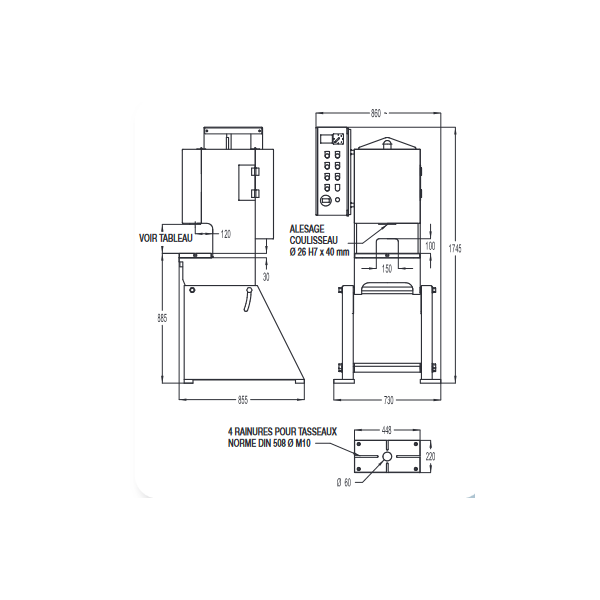

• Slider

The slider is made of cast iron FGS 300 mounted

on steel or bronze sliding rails, adjustable by

screws. The assembly is completely adjusted and

scraped manually. The adjustment is carried out by

stops mounted on the press frame.

The bedplate of the slider has holes and a central

bore for fixing tools.

The sliding rails have machining in the form of "oil

grooves" allowing an efficient lubrication.

A knock-out bar goes through the slider. The

adjustment is carried out by a stop mounted on the

frame.

• Connecting rod/Swivel screw

The connecting rod is made of FGS 300 cast iron

(steel on 80T) with bronze line completely scraped

ensuring a perfect lubrication. It is lubricated by oil.

The swivel screw is made of pre-treated steel,

completed by a surface treatment.

• Shaft

The shaft is made of hardened forged steel. An

over-sulfinization after machining reduces the wear

and tear due to friction. It runs on lubricated rings.

• Stroke change

The stroke change is achieved very quickly by

turning the disconnecting device a ¼” of a turn and

then selecting the desired Stroke length.

• Lubrification

The lubrication is centralized and ensured by a

manual pump. The frequencies are to be adapted

as per the cycles used (single or continuous stroke

working).

Automatic pump (optional).

• Twin-body solenoid valve

It is self-controlled and assembled with heavy duty

silencers.

• Clutch/Brake

The movements of the press are obtained by a

monodisc air clutch and managed by a brake. An air

reservoir compensates for the possible failures of

the network starting from the 25t model.

Standard equipments

• Two hand controls with push buttons.

• Central greasing by manual pump

• 6 digit counter with reset function, 8 digit counter

without reset function

• Single or continuous stroke

• 20° inclinable frame (option 45t and 80t)

• Regulation with or without motor

• Positive ejector in the slider

• Balancing cylinders (45t and 80t)

• Slider hydraulic unblocking (45t and 80t)

• Automatic unblocking for the stroke adjustment

(80t)

• EC compliance certificate

• User manual and electrical, pneumatic and

hydraulic diagrams

• Periodical verification guide (regulatory follow-up,

verification procedures, preventive maintenance,

faults and remedies)

Electrical equipment

•In compliance with European standards. It manages all the cycles: single, continuous, adjustment.

Paints

•Sky blue: RAL 5015

•Platinum grey: RAL 7036

Data sheet

- in good condition

- New

- Weight Kg (including packaging)

- 450 Kg

- Model

- Mechanical eccentric presses

- Tonnage

- 6T

4 other products in the same category:

Mechanical eccentric presse - 45T

Mechanical eccentric presse - 25T

.jpg)